The Chromate Disaster

- Markus Sommer

- Jul 17, 2025

- 3 min read

The end of excuses

A six-year project ends – a paradigm shift begins

After almost six years of research, literature review, field analysis, laboratory tests and industrial reactions, it is now official:

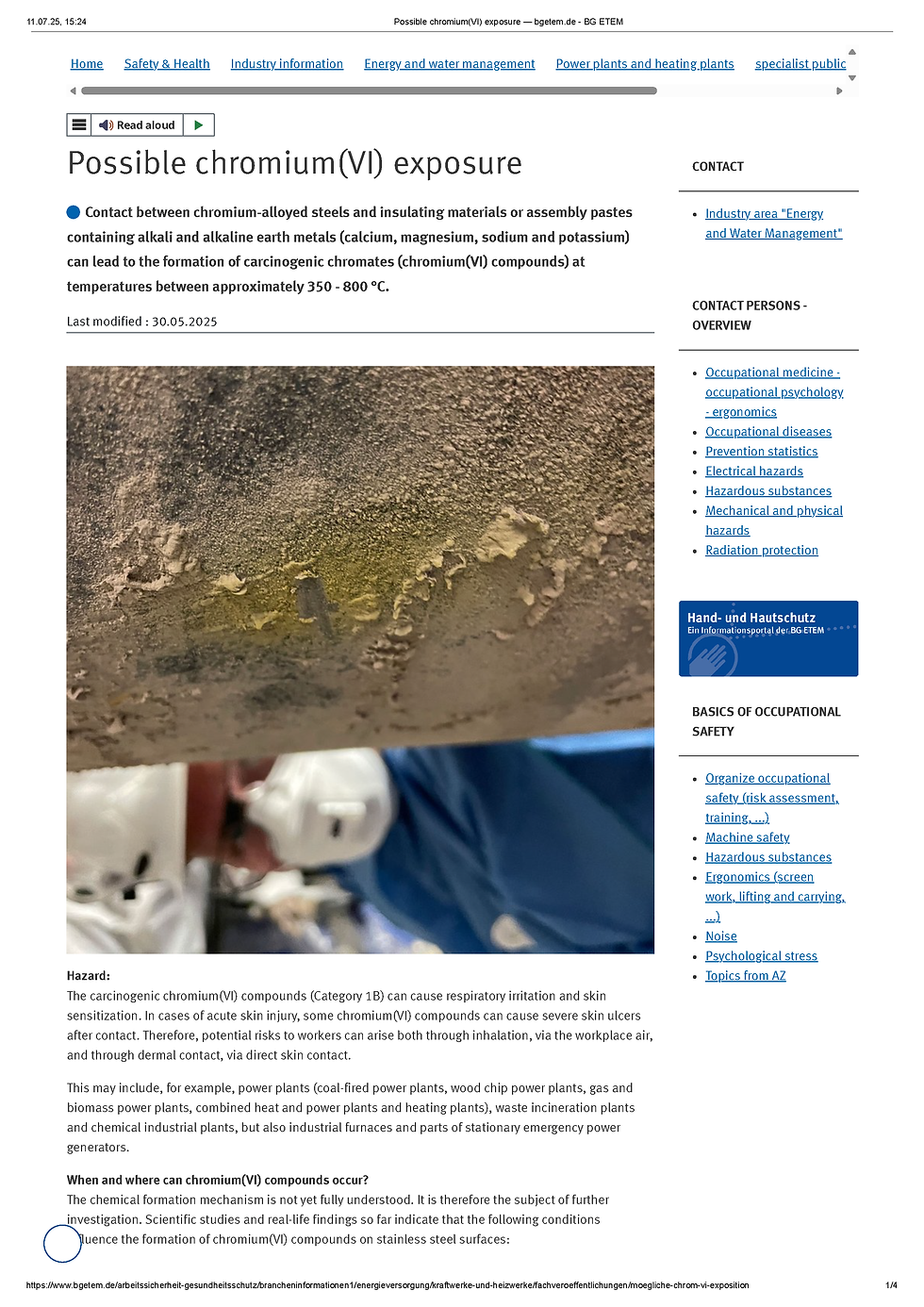

The formation of chromium (VI) compounds – particularly calcium and/or sodium chromate – through alkaline and/or alkaline earth insulation under power plant conditions is not only possible, but has been proven in practice many times and is also classified as a real risk by the employers' liability insurance associations.

when heat meets the wrong thing (chemistry doesn't lie)

For years, this blog has documented the danger of carcinogenic dusts that form on hot stainless steel parts due to improperly selected insulation materials. But now the time for warnings is over— we are at a turning point.

What we know:

With the publication of the evidence paper “The Chromate Disaster,” the final piece of the puzzle is put in place.

The literature and practice study covers over 40 pages and shows:

The thermochemical principles of chromate formation

The role of CaO/Na₂O in commercially available insulation materials

Reactive passive layer destruction on austenitic stainless steels

The scientific confirmation by Sayano, van Leeuwen & Verbinnen

Misinterpretations of the Tatar/Gannon studies by industry associations

The warnings from the manufacturers (Frenzelit, Jenbacher, MAN)

The regulatory consequences under EU law and national occupational health and safety

The criticism of the trivializing “neutralization”

Two professional associations, two clear signals

BG ETEM – Product Information from 30.05.2025

" Contact between chromium-alloyed steels and insulating materials or assembly pastes containing alkali and alkaline earth metals can lead to the formation of carcinogenic chromates (chromium(VI) compounds) at temperatures between approximately 350 and 800°C. "

This statement is a milestone in occupational safety, as it undermines all previous trivialisation strategies (Link to the BG ETEM article ).

BG BAU – July 2025

" Real findings and scientific studies indicate that, under certain conditions, chromium(VI) compounds (...) are detected on stainless steel surfaces and in commonly used insulating materials. ... The presence of thermal insulation materials containing alkali and alkaline earth metals (such as mineral wool or high-temperature glass wool) promotes the formation of chromates..."

This makes it clear: the problem, the chromate disaster, is also recognized by German accident insurers.

The technical information provided by the professional associations defines the "state of the art" and is therefore part of the general knowledge. Failure to act now is ignoring new, applicable protective obligations.

harmfuldust.com has been reporting since 2020:

Companies/operators who, despite the above-mentioned facts, continue to use calcium-containing insulation materials on stainless steel ° "carry on as before", i.e. ° do not update their risk assessment, ° do not use protective equipment, particularly during maintenance work, and above all ° do not carry out substitution testing and decisions, are acting knowingly, negligently and possibly even intentionally to the detriment of people and the environment.

The credibility of this blog site, which has often been questioned, is hereby more than proven.

What must happen now (as required by law):

Redefinition of risk assessment

Substitution decision

stricter occupational and environmental protection

Deinstallation and cleaning (decontamination)

Substitution application

Restoring a safe working environment

Research - Knowledge - Responsibility

We're now ending our research because the evidence is there, even though we're learning more every day; the industry's ignorance is also well documented.

Now we are researching the implementation of the consequences resulting from the analysis.

Welcome to the new era - Welcome to the age of consistency.

What we don’t (yet) know:

How will plant operators, insulation manufacturers, and insulation and service companies react? We'll, of course, report back ;)

Comments